Life Cycle Assessment of installations

What is Life Cycle Assessment?

Life cycle assessment is a methodology by which the environmental footprint of products and services are assessed over their entire life cycle. These environmental indicators can include Carbon footprint, water footprint, biodiversity indicator etc.

Carbon foot printing of new buildings via LCA is a compulsory requirement of the upcoming RE2020 regulations and it is already in experimentation via the E+C- program. In preparation for this future regulation, Building Solutions is carrying out carbon foot printing via LCA of its HVAC, HV, LV & Plumbing installations.

The LCA of a product includes 5 stages: extraction of raw materials and manufacturing, transport to the site, installation, use and end of life (recycling, disposal).

What is E+C- experimentation of the RE2020 and what implications for Building Solutions?

This is an experimentation for RE2020 of the environmental performance of Buildings which aims at:

- The generalization of positive energy buildings

- The deployment of low carbon footprint building

The deployment of low carbon footprint building is done by reducing the carbon footprint by using the indicators:

- IPCE: GHG emissions indicator for construction products and equipements. For example,

- IPCE for an HVAC installation is 157kgCO2/m2

- IPCE for a CFO installation is 116kgCO2/m2

- ICE: GHG emissions indicator for energy consumption.

We not being the manufacturer of the products that we install, we work with emission factors of our equipments published or derived via authorized sources. The objective: verified & transparent information to assess the carbon footprint of our facilities.

♦ Environmental declarations

The environmental declarations provide quantified information regarding the environmental characteristics of a building product or equipment. All authorized Declarations for building LCA can be found in the database INIES.

The declarations available can be specific and non-specific as follows:

◊ Product Environmental Profile (PEP)

Specific Declarations by manufacturers for electrical, electronic and HVAC products in France based on ISO standards. Outside of INIES, these declarations can also be found at http://www.pep-ecopassport.org/find-a-pep/

◊ Default Environmental Declaration (DED)

In the absence of PEPs for products, the declarations used are known as default environmental declarations (DEDs) published by the French Government.

These DEDs are frequently based on the PEPs. Safety factors are included in these DEDs in the following manner:

- + 100% – when only one PEP available

- + 50% – when several PEPs available

- + 30% – in the absence of PEPs, LCA done using generic data.

♦ Building Solutions Tool for LCA of an installation:

Vinci Energies has currently collaborated with NOOCO – a startup for carbon foot printing in the building sector – for our HVAC, HV, LV and Plumbing installations. It accumulates all the environmental declarations available on the market (updated regularly) and uses statistical analysis to account for carbon emissions.

♦ Case study of a HVAC installation:

The histogram below shows the carbon foot printing results over 50 years (excluding utilization phase) of an HVAC installation via NOOCO.

The total carbon footprint per m2 of the installation is:

- IPCE : Fabrication + Distribution + Installation+ End of Life = 221 kgs CO2/m2 which is higher than the maximum possible value = 157 kgs CO2e./m2.

- Usage = 108 kgs CO2/m2.

Strategies to reduce the carbon footprint:

Building Solutions proposes various strategies to help reduce your carbon footprint. A few propositions are shown below:

- Using recycled steel in place of new steel

Steel is completely recyclable, and the inherent properties of steel do not change when it is recycled, and steel can be recycled over and over again. We can reduce the carbon footprint of steel pipes and ducts used in the project by up to 50% with 80% local recycling at the end of life.

- Purchasing products with environmental declarations (PEPs in France)

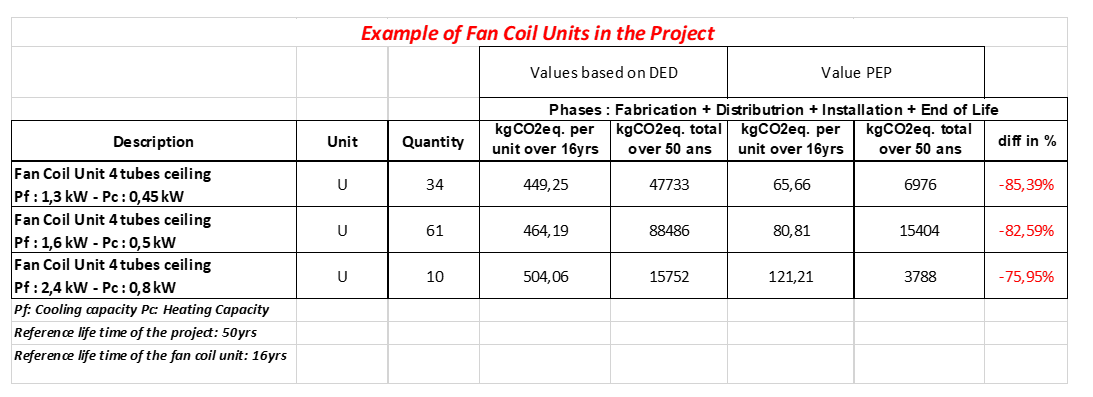

Since in this project, only 5% of the products have PEPs available, insisting on environmental declarations can reduce the footprint as default declarations include safety factors which exaggerates the footprint by about 30% (sometimes 80% as shown in the table below).

Did you like the article ?